<kbd id="ll4ng"></kbd>

Brief introduction of new type closed multi speed winch hoist

At present, the domestic and foreign winch hoists always operate at a speed when opening and closing the gate. When multi speed is required, the frequency conversion technology is usually used. However, the motors configured by the frequency conversion technology are selected according to the maximum power when working, which will inevitably lead to the waste of motor power and the low efficiency of the hoist. In order to ensure the high efficiency of the hoist and the reasonable configuration of the motor power, the actual working conditions of the hoist shall be operated as follows:

Operating condition table of hoist

Working condition configuration item | Gate operation condition | |||||

The gate is open | After opening the gate | Gate out of water | The gate is closed | The gate is closed | The gate is closed | |

Gate operating speed | low speedV1 (0.1~0.5m/min) | Medium speedV3 (1~2m/min) | Higher speedV2 (3~5)m/min | high speedV4 (3~5)m/min | Medium speedV3 (1~2m/min) | low speedV1 (0.1~0.5m/min) |

Motor power configuration | Low power | High power | High power | High power | High power | Low power |

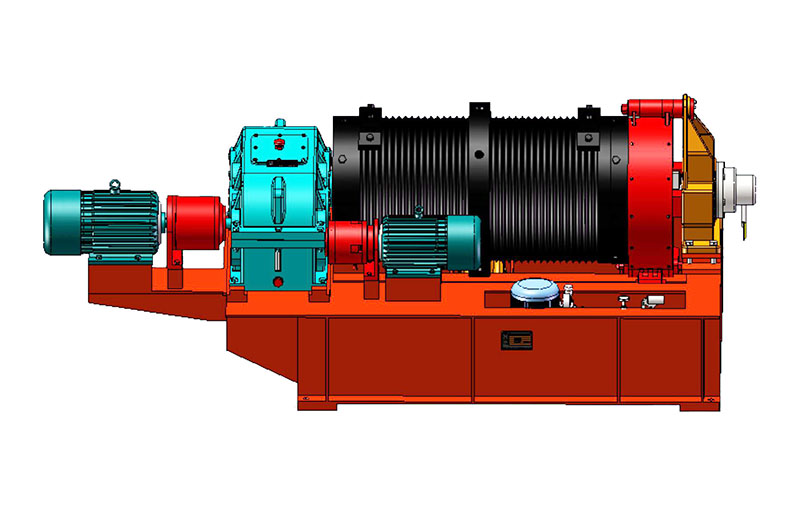

According to the above working conditions, we have developed a new generation of closed multi speed winch hoist based on the new type of closed winch hoist. The hoist adopts chcd type gear linked ring less tooth difference multi speed reducer with large bearing capacity, strong overload resistance, large speed ratio, large load ratio, small volume, variable speed ratio, safe and reliable, which is directly connected with the drum to realize closed transmission. The chcd type gear linked multi speed reducer with small tooth difference adopts double shaft input and single shaft output. The double shaft input is equipped with two motors with different powers. Under the condition of using non adjustable speed motor as power, it can realize four kinds of single shaft speed output, and the mechanical speed regulation range is wide. In addition to the characteristics of the new type closed multi speed hoist, its outstanding features are as follows:

1. Under the condition that the non speed regulating motor is the power, the hoist can open and close the gate at four speeds according to the working conditions, and the mechanical speed regulation range is wide;

2. The chcd type multi speed gear reducer with small tooth number difference adopted by the multi speed hoist has the characteristics of multiple transmission ratio output, and the multiple of the maximum transmission ratio and the minimum transmission ratio can reach 100, and the transmission ratio of the reducer can be larger than that of the small one;

3. The chcd type gear linked multi speed reducer with less tooth difference is adopted for the multi speed hoist, which can realize the mechanical speed regulation according to the needs of the equipment working speed, which can more effectively ensure the reliability and safety of the equipment, thus improving the working efficiency of the equipment;

4. When the hoist opens and closes the gate, different working conditions require different working speed and different motor power. Due to the multi speed reducer adopted by the hoist has the characteristics of multiple transmission ratio output, the ordinary motor with corresponding power can be matched according to the working speed of the hoist, which greatly reduces the working energy consumption of the hoist. Compared with the variable frequency speed control system, the control system of the ordinary motor is more simple and reliable, the manufacturing and maintenance cost is lower, and the use is more safe and reliable.